Introduction

The oil and gas industry operates in a complex, high-risk environment where operational efficiency, safety, and cost management are critical. Digital twin technology—virtual replicas of physical assets or processes—is transforming how this sector monitors, manages, and optimizes its operations. By integrating real-time data with advanced simulations, digital twins enable companies to predict issues, enhance safety, and drive operational excellence.

This blog explores practical use cases, benefits, common challenges, and solutions related to digital twins in oil and gas.

What is a Digital Twin in Oil and Gas?

A digital twin is a dynamic, virtual model mirroring the behavior of physical oil and gas assets like pipelines, refineries, or drilling rigs. Using IoT sensor data, AI, machine learning, and cloud computing, it provides continuous insights into performance, condition, and potential risks.

Use Cases of Digital Twins in Oil and Gas

1. Predictive Maintenance

Digital twins monitor equipment health to forecast failures before they happen, minimizing unplanned downtime and repair costs.

2. Asset Lifecycle Management

Virtual replicas track assets from design and construction through operation to decommissioning, optimizing utilization and ROI.

3. Remote Monitoring and Control

Operators can manage offshore platforms and remote sites through digital twins, making real-time data-driven decisions.

4. Process Optimization

Simulations help refine production workflows, reduce energy consumption, and enhance output quality.

5. Workforce Training & Safety Simulations

Virtual environments enable safe training for hazardous scenarios, improving preparedness and reducing accidents.

Benefits of Digital Twin Technology

-

Increased Operational Efficiency by providing real-time monitoring and data-driven insights.

-

Enhanced Safety and Risk Management through virtual testing of scenarios and predictive alerts.

-

Cost Reduction from optimized maintenance, less downtime, and efficient resource allocation.

-

Sustainability Improvements by reducing emissions and aligning with environmental regulations.

-

Improved Decision-Making leveraging AI and analytics integrated with digital twins.

Challenges in Digital Twin Adoption

-

Data Integration Complexity from heterogeneous sources and formats.

-

High Initial Investment and Implementation Costs.

-

Cybersecurity Risks associated with connected assets.

-

Skills Gap in digital technologies and change management.

-

Data Privacy and Ownership Concerns.

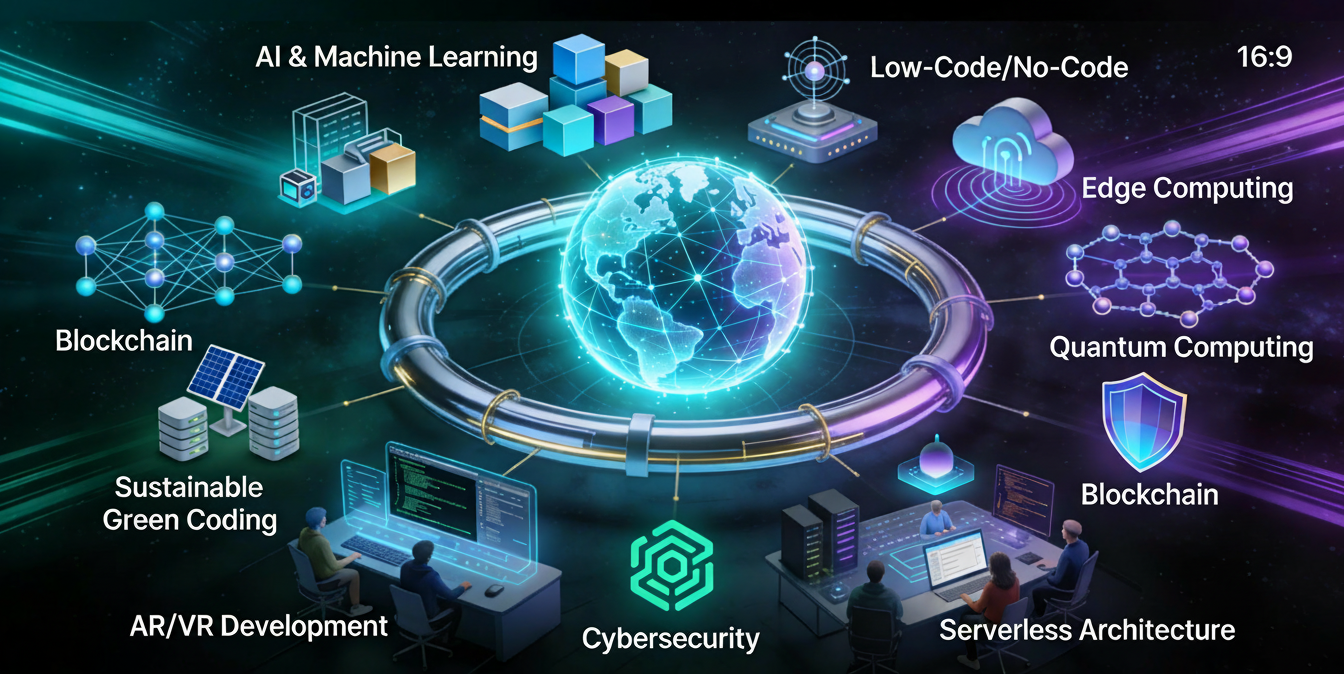

Solutions and Best Practices

-

Use cloud-based digital twins to reduce upfront costs and improve scalability.

-

Integrate AI, IoT, and blockchain to enhance analytics, security, and data integrity.

-

Invest in digital upskilling and training for workforce readiness.

-

Develop comprehensive data governance policies to address privacy and compliance.

-

Pilot projects with clear KPIs to demonstrate ROI and gradually scale adoption.

Conclusion

Digital twin technology offers transformative potential for the oil and gas industry by enabling smarter, safer, and more efficient operations. Despite challenges, the integration of digital twins with AI, IoT, and cloud computing will redefine future energy production and asset management.

For tailored digital twin solutions and AI consulting in oil and gas, explore TechOTD AI Services and continue learning through the TechOTD Blog.