Introduction

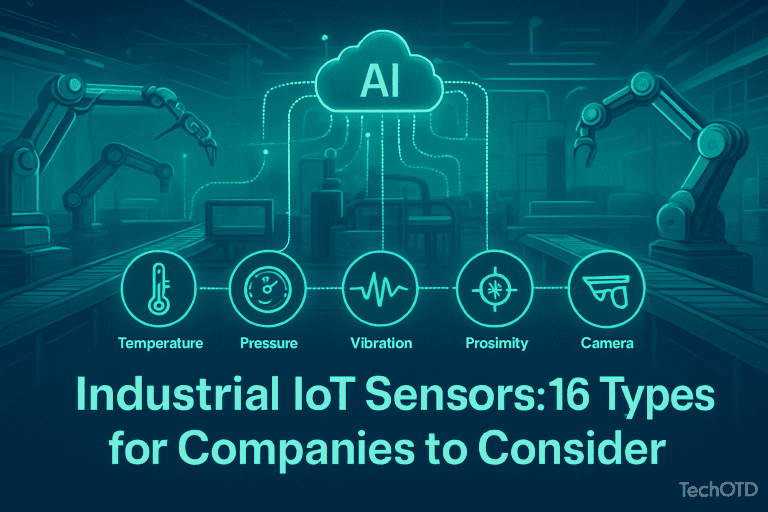

In today’s rapidly advancing manufacturing and logistics landscape, Industrial Internet of Things (IIoT) sensors play a pivotal role in driving smart factories, real-time monitoring, and predictive analytics. From automating routine processes to enabling proactive maintenance and sustainability insights, the right IoT sensors transform how companies operate and compete. This comprehensive guide reveals 16 essential types of IIoT sensors modern enterprises should consider—plus actionable advice, real-world applications, and expert resources from TechOTD to future-proof your connected operations.

Understanding Industrial IoT Sensors

IIoT sensors are the building blocks of the smart industry. By capturing, transmitting, and analyzing physical phenomena (temperature, pressure, motion, etc.), they empower businesses to:

-

Automate machine monitoring and control.

-

Predict and prevent equipment failures.

-

Boost energy efficiency and reduce costs.

-

Improve workplace safety and compliance.

-

Gain data-driven insights for better decision-making.

Leading-edge sensor integration often includes AI, cloud analytics, and seamless custom development—discover what’s possible with TechOTD’s AI Services.

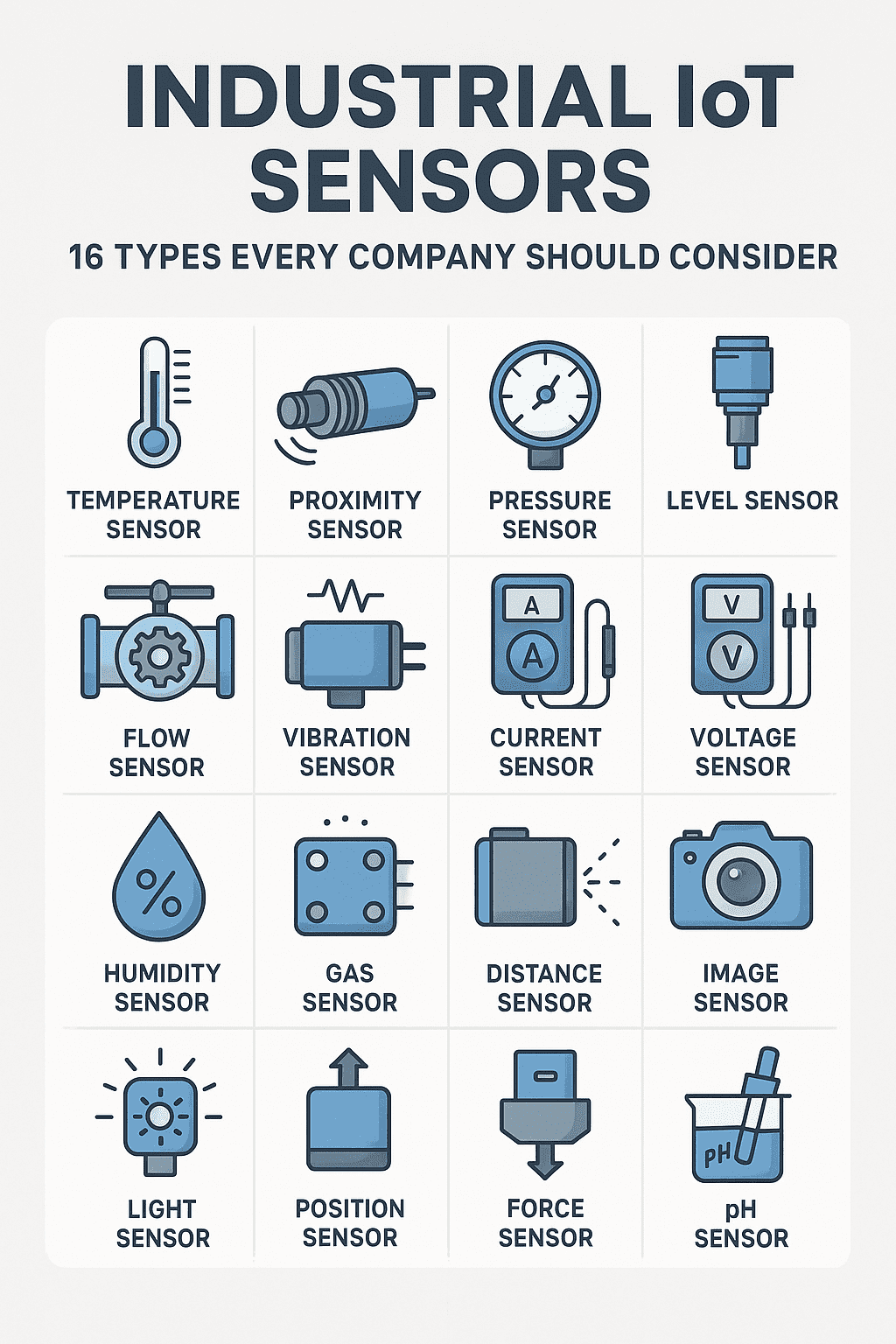

16 Types of Industrial IoT Sensors to Power Your Business

1. Temperature Sensors

-

Monitor equipment, products, and environments to prevent overheating, freezing, or spoilage.

-

Use Cases: Cold chain logistics, HVAC, manufacturing.

2. Pressure Sensors

-

Track fluid or gas pressure in pumps, pipelines, and tanks to prevent leaks or maintain optimal operation.

-

Use Cases: Oil & gas, chemical processing, water utilities.

3. Proximity Sensors

-

Detect presence or absence of objects—crucial for automation and safety interlocks.

-

Use Cases: Conveyor lines, robotics, packaging lines.

4. Vibration Sensors

-

Identify abnormal equipment vibrations indicating wear, imbalance, or impending breakdown.

-

Use Cases: Predictive maintenance, rotating machinery, motors.

5. Humidity Sensors

-

Measure moisture levels to ensure safe storage and ideal production conditions.

-

Use Cases: Food processing, electronics, pharmaceuticals.

6. Flow Sensors

-

Monitor the movement of liquids or gases for efficient control and billing.

-

Use Cases: Water treatment, chemical processing, energy management.

7. Level Sensors

-

Detect levels of liquids, solids, or granular materials in tanks and silos.

-

Use Cases: Bulk storage, process industries, agriculture.

8. Accelerometers

-

Track acceleration, tilt, and motion—enabling asset tracking and machine condition monitoring.

-

Use Cases: Fleet management, machine health, smart logistics.

9. Gas Sensors

-

Detect hazardous gases and pollutants to prevent accidents and ensure compliance.

-

Use Cases: Mining, utilities, manufacturing, building management.

10. Optical Sensors

-

Leverage light for object detection, counting, and quality inspection.

-

Use Cases: Automated sorting, vision-based inspection, packaging.

11. Current/Voltage Sensors

-

Monitor electrical consumption, surges, and overloads for operational efficiency and safety.

-

Use Cases: Energy management, predictive maintenance, power distribution.

12. Ultrasonic Sensors

-

Measure distance, detect objects, or monitor fluid levels using sound waves.

-

Use Cases: Robotics, logistics automation, tank level detection.

13. Magnetic Sensors

-

Detect magnetic fields or positions for speed, position, and rotational measurements.

-

Use Cases: Conveyor belts, electric motors, proximity detection.

14. Infrared (IR) Sensors

-

Enable temperature measurement and motion detection using infrared radiation.

-

Use Cases: Safety systems, automated lighting, thermal monitoring.

15. Force/Torque Sensors

-

Measure mechanical force or torque in manufacturing processes for quality control.

-

Use Cases: Robotics, assembly lines, pick-and-place operations.

16. Image Sensors (Cameras)

-

Capture and process images for AI analysis, defect detection, and remote monitoring.

-

Use Cases: Production line inspection, security, operational dashboards.

Integrating IIoT Sensors for Maximum Value

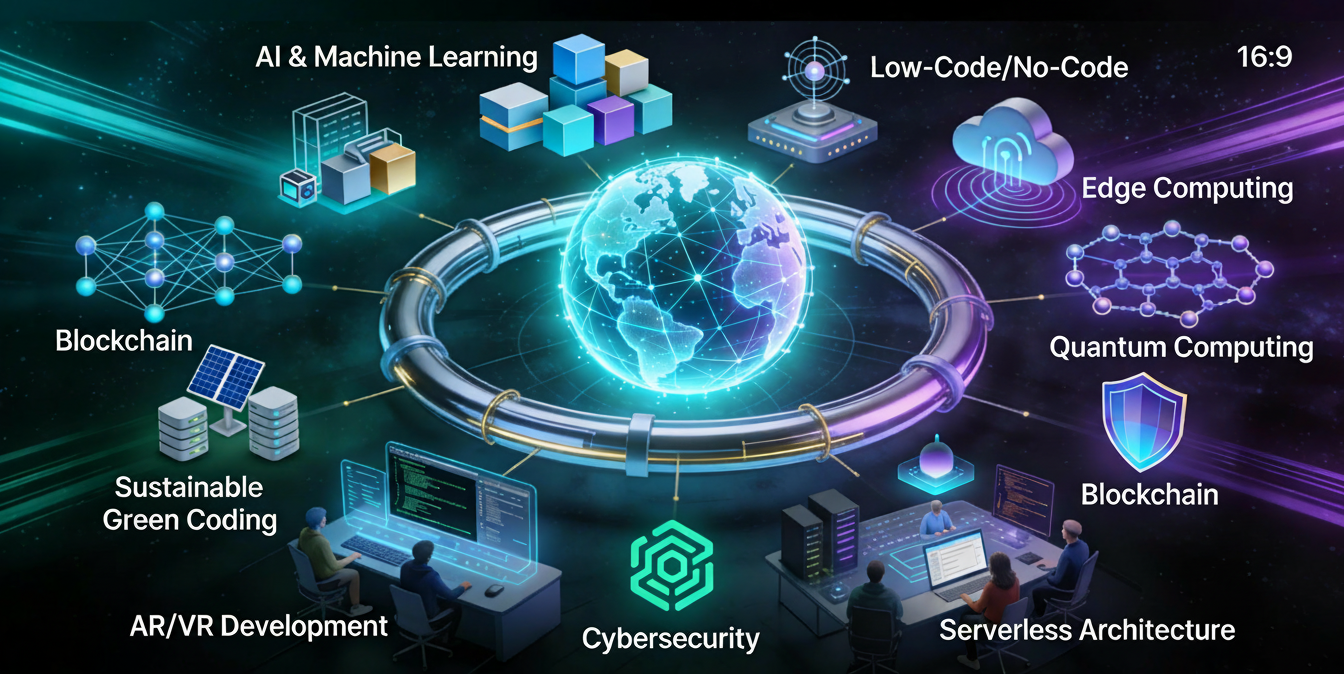

Modern businesses achieve transformative benefits by integrating these sensors with:

-

Cloud platforms for scalable analytics (Connect with TechOTD)

-

AI and machine learning for predictive maintenance and insight generation (Next-gen AI Solutions)

-

Custom dashboards for real-time, actionable views (Partner Programs)

-

Industry-focused use cases like eCommerce logistics, manufacturing, or smart buildings (Industry Solutions)

Conclusion

The future of industrial operations is data-driven, intelligent, and interconnected. By strategically deploying these 16 IIoT sensor types, your company unlocks new levels of visibility, efficiency, and innovation. Ready to design a future-proof sensor network or need world-class AI integration for manufacturing, logistics, or energy? Start your digital transformation journey with TechOTD’s expert solutions.

FAQ

1. What are the most popular IIoT sensor types for 2025?

Temperature, pressure, vibration, and proximity sensors lead deployments in manufacturing and logistics.

2. How can IIoT sensors save costs for my business?

They enable predictive maintenance, reduce downtime, optimize processes, and cut energy/waste expenses.

3. Is integrating multiple sensor types complicated?

With the right partner and modular platforms like TechOTD, multi-sensor integration is streamlined and scalable.

4. Are IIoT sensors secure?

Partner with trusted providers that prioritize data security, encryption, and compliance for safe operations.

5. How do I choose the right mix of sensors?

Analyze your process needs, consult with IIoT and AI experts, and start with scalable pilot projects.